Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

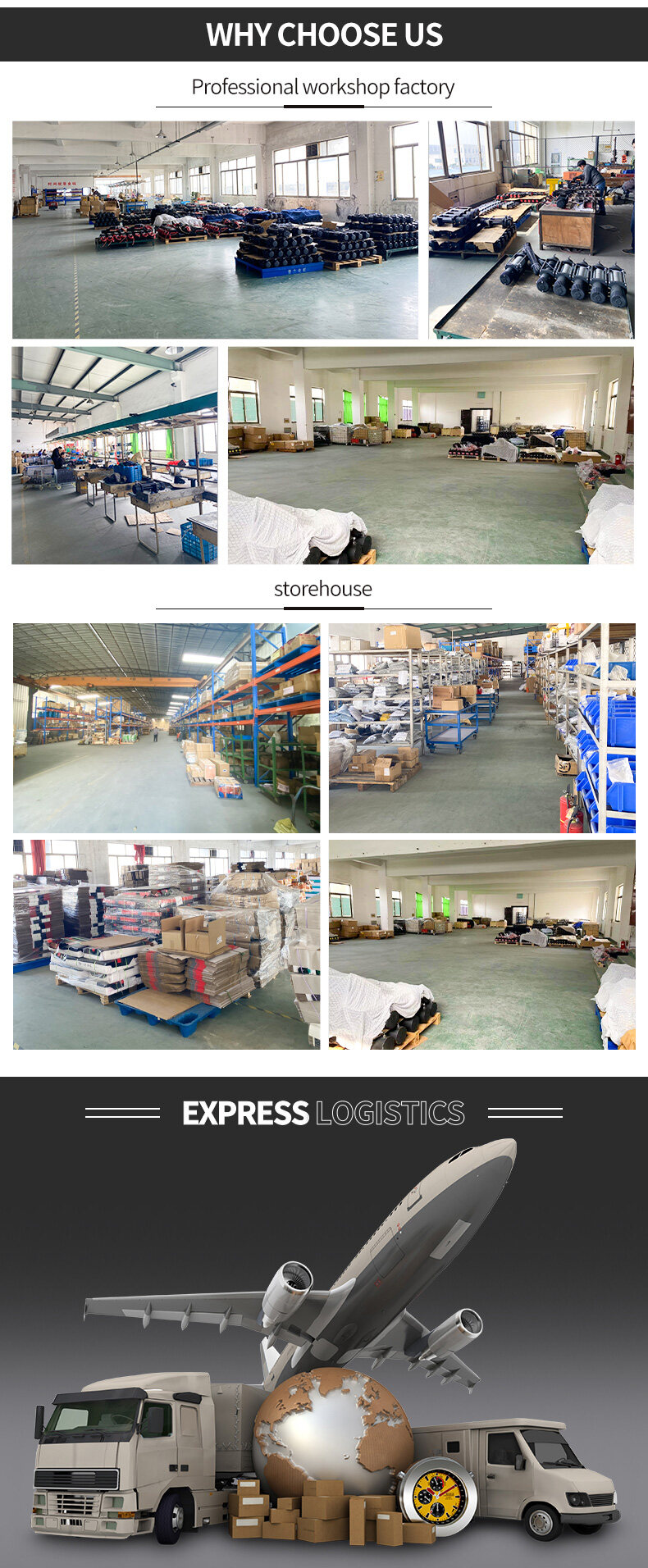

Auto-Cross country —— The best choice for field sport. WORKER is a highly specialised winch manufacturer situated in Ningbo, Zhejiang province, the most developed area in Changjiang, now the economic hub of China. Our premises cover an area of 16000 square meters, comprising more than 15,500 square meters of factory floor space and offices for our 100-plus employees. Our manufacturing plant has state-of-the-art assembly lines, together with in-house precision die-casting, CNC machining, heat treatment, polishing, high-pressure cleaning and finishing facilities.

We also have the most advanced, fully-automated intelligent electric motor and winch testing facilities in the winch industry, to ensure the very highest standards of product reliability and durability. Established in 2005,WORKER began a highly progressive and intensive R & D programme into winch design, using the very latest in technology, to improve product performance and efficiency in production. We currently own patents on our many improved winch design features and strive to maintain our unsurpassed build-quality and outstanding value.

We have passed CE CERTIFICATE, TUV CERTIFICATE, IATF 16949 CERTIFICATE, ISO14001:2015 CERTIFICATE and ISO9001:2000 CERTIFICATE.

Parts assembly - Finished product assembly - Inspection and testing - Packing into boxes

We support sea, air and land transportation, delivery to door point (refer to WE COULD BY SEA OR AIR OR DOOR TO DOOR SHIPPING). Products are generally shipped within 35 days, according to the product to provide bubble and carton packaging to ensure product safety.

Q: What is the MOQ?

A: Each product has different requirements, please contact us for specific products.

Q: What is your delivery time?

A: 35-40 days

Q: What is the payment method?

A: 30% PAYMENT AFTER CONFIRMED THE ORDER, 70% PAYMENT WHEN WE ARE READY TO SHIP.

Q: How do you guarantee the quality of the products?

A: We have strict factory testing to ensure the quality of each product.

Q: Are you a factory or a trading company?

A: The integration of industry and trade.

Q: Where is your factory?

A: Ningbo, if you want to visit, you can contact us.

Q: Are customized services available?

A: As long as you tell us your needs, we will provide you with customized solutions.

Q: Do you support OEM and ODM?

A: We support OEM and ODM services, if you need, you can contact us.

Q: Why choose us?

A: We are a professional manufacturer, focusing on the manufacture of 4*4 auto parts.

Strict inspection and testing process to ensure the quality of each product.

High-quality after-sales service to solve every problem related to auto parts.

Q: How long is the product warranty period?

A: 1-3 years.

Reliable power mechanism

The electric winch adopts an all copper motor coated aluminum alloy shell, which is durable, corrosion-resistant, high efficiency, low noise, instant cooling effect and suitable for long-term use.

Amazing lifting capacity

Thanks to a series of advanced technology and design, our garage elevator meets various requirements for strength and hardness.

Excellent workmanship

Our products are well designed, including high-quality alloy steel hook and aluminum alloy shell. This Jeep hardtop crane can be used for a long time and ensures stability and durability.

Durable materials

Our products are well designed, including high-quality alloy steel hook and aluminum alloy shell. This Jeep hardtop crane can be used for a long time and ensures stability and durability.

Large load bearing

Thanks to a series of advanced technology and design, our garage elevator meets various requirements for strength and hardness. Single line capacity up to 660 pounds / 300 kg, double line capacity up to 1320 pounds / 600 kg.

The electric winch is the standard configuration of the off-road vehicle. It is also the partner of the crane on the construction site. It is also an indispensable lifting tool for the rescue tripod. As a mechanical device that can lift and move heavy objects, as long as the steel wire rope is wound on the drum or axis, it can achieve the effect of labor-saving traction.

In 2020, the global electric winch market sales reached USD 845.39 million and is expected to reach USD 1188.77 million in 2027, with a compound annual growth rate (CAGR) of 4.93% (2021-2027). In the next few years, the industry will have great uncertainty. The forecast data for 2021-2027 in this article is based on the historical development of the past few years, the opinions of industry experts, and the opinions of analysts in this article.

From a regional perspective, the Chinese market has changed rapidly in the past few years. In 2020, the market size is 96.88 million US dollars, accounting for about 11.46% of the global market. It is expected to reach 142.89 million US dollars in 2027, when the global share will reach 12.02% .

From the perspective of product market applications, vehicles are the most important application area. A total of 445.1 thousand winches were used in vehicles in 2020, accounting for 50.46% of the total market sales. There are also 407.1 thousand winches used in factories, accounting for 46.15% of the total sales in the market.

In terms of product type and technology, single-drum winches occupy a major market share, with a market size of USD 570.56 million in 2020, accounting for 67.49% of the market size. Followed by the double-drum electric winch, accounting for 27.48%.

In 2020, the share of major manufacturers will exceed 36%. It is expected that the industry competition will become more intense in the next few years, especially in the Chinese market.